Tropical

Forest Exclusive Product

Get the highest class decking you deserve and forget about maintenance for years! We have handpicked the best kiln-dried wood to provide you with the finest appearance for your dream deck projects.

Tropical Forest exclusive Product

Get the highest class decking you deserve and forget about maintenance for years! We have handpicked the best kiln-dried wood to provide you with the finest appearance for your dream deck projects.

Why Ipe Black label decking?

- Chemical-free, natural wood

- Controlled Wood moisture content

- Exceptional weather performance

- Fully wrapped bundles with woven bags

- Strong wood that does not splinter, break or scratch easily

- Naturally rot, mould and termite resistant

- Exceptional return on investment with decking that can last 70+ years!

- IPE Black Label can be shipped worldwide!

IPE Black label mix beauty and natural resistance ideal for decks, terraces, patios, gazebos, fences, sidings and other exterior architecture.

Why Ipe Black label decking?

- Chemical-free, natural wood

- Controlled Wood moisture content

- Exceptional weather performance

- Fully wrapped bundles with woven bags

- Strong wood that does not splinter, break or scratch easily

- Naturally, rot, mould and termite resistant

- Exceptional return on investment with decking that can last 70+ years!

- IPE Black Label can be shipped worldwide!

IPE Black label mix beauty and natural resistance ideal for decks, terraces, patios, gazebos, fences, sidings and other exterior architecture.

Member and Certified

Member and Certified

AVAILABLE SIZES

WE SUPPLY QUALITY IPE BLACK LABEL DECKING TO ALL PROVINCES IN CANADA

Tropical Forest Products imports Ipe Black Label directly from South America and our staff selects high-quality lumber to meet our clients’ needs. With years of experience providing decking, we are great partners whether you are looking for Ipe Black Label decking for a small residential project, a large-scale commercial project, or a size in between. Our team is committed to ensuring successful lumber and decking delivery for your project.

Our boards are available in all major widths and lengths and we can create custom profiles upon request. If in doubt, give us a call to discuss what your project requires. Our team can check inventory, understand time constraints and shipping requirements, so you have a clear picture of availability and pricing.

Patio Ipe Black Label wood

Ipe Black Label wood decking

Terrace Ipe Black Label wood

WHICH PROFILE IS RIGHT FOR YOU?

Require a consultation for your project? Fill out the form below and speak to an expert about your Ipe Black Label decking and lumber requirements. We regularly talk to architects and designers for custom profiles.

WHY IPE Black label DECKING IS BEST

Ipe Black Label is an ecologically friendly wood choice, highly regarded for its ability to resist rot, insect attack, and mold, without requiring the use of toxic chemicals that must be used on other decking wood to give them similar properties. Ipe is extremely dense and strong and its high wear durability makes it far more resistant to cracks and splintering. This is why Ipe Black Label decks can last for decades. Ipe Black Label is rated ‘High 70+ years’ for its decay resistance, though it tends to last much longer… if only there were a higher rating! Ipe shrugs off weather, with little effect on its structural integrity. Like metal for fire resistance, Ipe Black Label is rated an excellent ‘A1’.

Over time, the sun will change the color of the wood from the initial red-brown to a stunning silver patina. Best of all, when you buy Ipe Black Label from Tropical Forest Products you know your wood has been harvested from legally demarcated sustainable forests.

Ipe Black Label is an extremely economical and eco-friendly alternative to other types of wood, especially when the life cycle is considered. When the cost of materials and labor is compared to alternative decking materials, Ipe Black Label’s lifespan puts it far in the lead. Compared to other decking materials like redwood cedar, composites, and torrefied woods, Ipe Black Label is very competitively priced – but Ipe Black Label’s lifespan and properties make it by far the superior option.

IPE Black label IS FIVE TIMES STRONGER THAN TREATED WOODS AND CEDAR!

Ipe Black Label | Cedar | Redwood | Treated pine/ CCA | |

Appearance | Does not splinter, surface resists damage and remains smooth, the sealer is required, turns to silver-grey patina over time | Splinters and scratches easily, without regular sealing becomes grey | Splinters and scratches easily, without regular sealing becomes black | Boards twist and cup, the surface shows splits and checks, without regular sealing becomes grey-green and rough |

Grade | All heart no sap, select grade | Knots and sap in common grade, grades vary | Knots and sap in common grade, grades vary | Numerous defects in grade |

Resistance to termites | High resistance | Low resistance | Low resistance | Depends on treatment |

Decay resistance | High 50+ years | Moderate 10-15 years | Moderate 10-15 years | Depends on treatment |

Resistance to marine borers | High | High | Low | Medium-high |

Fire resistance | A | B-C | B-C | C-D |

Moment in service | Low | Medium | Medium | Medium-high |

Bending strength | 25,400 psi | 6,800 psi | 7,900 psi | 14,500 psi |

Max shear strength | 2060 | 900 | 940 | 1370 |

Hardness | 3680 lbs | 580 lbs | 480 lbs | 870 lbs |

Weight per cubic foot | 69 lbs | 30 lbs | 30 lbs | 35-40 lbs |

WHY IPE BLACK LABEL FOR DECKING IS THE OBVIOUS CHOICE

- Lasts 70+ years

- Low maintenance

- Resistant to termites

- No knots

- Excellent for docks

- Beautiful grain

- Huge selection of sizes

- High density

- Resistant to shifts/bending

- Resists scratches

- Almost 2X as strong as Oak

- Environmentally friendly

- Easy to install

- Sustainable forestry

- Class A fire rating

- Resistant to mould and fungi

- Excellent slip resistance

- Boards up to 20 feet long

- We custom mill to your dimensions

- Used on world-famous projects (eg.Coney Island in New York)

- Resists splinters

- Competitively priced

Decking

Profiles

| Nominal | Net | Available Lengths | Application |

| 1″x 4 “ | 3/4″ x 3-1/2″ | 3′ to 20′ | Privacy screens, Fences |

| 1″x 6 “ | 3/4″ x 5-1/2″ | 3′ to 20′ | Privacy screens, Fences, Decks |

| 1″x 6 ” Pregrooved | 3/4″ x 5-1/2″ | 3′ to 20′ | Decks Floors, Screens, Fences |

| 1″x 8 “ | 3/4″ x 7-1/4″ | 3′ to 20′ | Fascias, Countersteps |

| 1″x 10″ | 3/4″ x 9-1/4″ | 3′ to 20′ | Fascias, Cladding Posts-Columns |

| 1″x 12″ | 3/4″ x 11-1/4″ | 3′ to 20′ | Fascias, Cladding Posts-Columns |

| 5/4″ x 4″ | 1″ x 3-1/2″ | 3′ to 20′ | Decks Floors, Screens, Fences |

| 5/4″ x 6″ | 1″ x 5-1/2″ | 3′ to 20′ | Decks Floors, Screens, Fences |

| 5/4″ x 6″ Pregrooved | 1″ x 5-1/2″ | 3′ to 20′ | Decks Floors, Screens, Fences |

| 5/4″ x 8″ | 1″ x 7-1/4″ | 3′ to 20′ | Fascias, Countersteps |

| 5/4″ x 10″ | 1″ x 9-1/4″ | 3′ to 20′ | Fascias, Cladding Posts-Columns |

| 5/4″ x 12″ | 1″ x 11-1/4″ | 3′ to 20′ | Fascias, Cladding Posts-Columns |

| 2″ x 2″ | 1-1/2″ x 1-1/2″ | 3′ to 20′ | Balusters, Decorative Walls |

| 2″ x 4″ | 1-1/2″ x 3-1/2″ | 3′ to 20′ | Handrail, Decorative Walls |

| 2″ x 6″ | 1-1/2″ x 5-1/2″ | 3′ to 20′ | Heavy Duty Deck Floors, Pergolas |

| 2″ x 8″ | 1-1/2″ x 7-1/4″ | 3′ to 20′ | Pergolas, Structures |

| 2″ x 10″ | 1-1/2″ x 9-1/4″ | 3′ to 20′ | Pergolas, Structures |

| 2″ x 12″ | 1-1/2″ x 11-1/4″ | 3′ to 20′ | Pergolas, Structures |

| 4″ x 4″ | 3-1/2″ x 3-1/2″ | 3′ to 20′ | Posts, Columns, Structures |

| 6″ x 6″ | 5-1/2″ x 5-1/2″ | 3′ to 20′ | Posts, Columns, Structures |

| 3″ x 6″ | 2-1/2″ x 5-1/2″ | 3′ to 20′ | Heavy Duty Floors, Structures |

| 3″ x 8″ | 2-1/2″ x 7-1/4″ | 3′ to 20′ | Heavy Duty Floors, Structures |

SIDING Ipédex V-joint profile | 7/8″ x 5″ | 3′ to 20′ | Siding, cladding, soffits |

IPe Black label TILES AND CONNECTORS

Ipe Black Label Tiles Standard Sizes

20″ x 20″ – 24″ x 24″

(Smooth or Anti-slip profiles)

Custom Sizes Such As

24″ x 36″ – 36″ x 72″ – 48″ x 96″

Are available by special order only.

Ipe Black Label Decking Tile Connectors

24″x24″ Ipe Black Label Decking Tiles, Perfect for Rooftops

Adjustable Deck Pedestals

Decking

installation

HANDLING AND STORING IPE Black Label DECKING BEFORE INSTALLATION

Boards should be stacked evenly on bolsters, which allows airflow from underneath. If the boards will be stored outdoors, make sure to cover the top and sides. Sufficient ventilation is very important for keeping cupping to a minimum and for preserving the long-term stability of the lumber.

Deck planning is crucial for the longevity of the boards and to prevent the build-up of humid air under the wood, which will permeate into the boards. Correctly planned airflow channels will allow air to flow from under the deck, between the joists, and through the gaps between the boards.

The design of the deck also needs to enable cross ventilation to minimize the chances of cupping and surface checking of the boards. This will reduce the natural tendency of wood to move in use. We suggest at least 18” of open-air under the joists and open side for sufficient airflow. If skirting is installed, it must be ensured it does not hinder sufficient cross ventilation. The ground should be sloped sufficiently to prevent water from standing under the deck, which is why installing a deck above a concrete pad is not recommended. Concrete raises the risk of water retention, and boards will tend to cup and crown.

INSTALLATION GUIDELINES

For joists and concealed structural parts, cedar, metal, or pressure-treated wood may be preferred. Joist heads can be protected by a membrane to make the structure last longer.

Ipe Black Label decking gets its long-lasting durability from a natural alkali. Take care while working with Ipe Black Label as the fine yellow dust that is produced during moist operations can cause dermatitis. Prolonged inhalation of sawdust also should be avoided. Make sure to wear eye protection and wash up properly after handling the wood. Due to the high density of the wood, pre-drilling and countersinking is suggested between screwing and nailing. Carbide saw blades and quality drill bits are also recommended.

MAKE SURE YOU USE HIGH-QUALITY STAINLESS STEEL SCREWS

Steel, iron, galvanized and coated products can cause black staining and generally have a shorter life than Ipe wood itself. Proper fastener length is usually the thickness of the wood multiplied by a minimum factor of 2.5. Also use two screws per joist to attach the decking.

A minimum 3/32” gap between Ipe Black Label decking boards is recommended to ensure adequate airflow and drainage. End to end butt joints will be installed without gap, but once the wood us seasoned a 1/8” shrinking on 6” boards is expected. In hot and dry climates, expect additional shrinkage. If that’s the case, kiln dried lumber and appropriate fastener must be considered.

Alternative screw and plug: Pre-drill and counter bore decking board up to 1/4″; drive in the screw and lightly tap and glue a 3/8” diameter plug in every hole with marine grade epoxy. Sand for a flush finish.

FINISHING

Ipe Black Label decking can be oiled to maintain its natural color or be left alone to weather to a beautiful silver patina. The high density of the wood means it doesn’t require any treatment to be durable.

We believe this information should be helpful and hope it is accurate. However, Tropical Forest Products does not assume any liability for the information provided. Installers are solely responsible for safe installation. Follow manufacturers’ recommendations and ensure designs are validated by a structural engineer.

Decking

Maintenance

MAINTAINING IPE Black Label DECKING

After installation

Ipe Black Label boards have a natural finish and are ready to be sanded lightly after installation. Use a 5” electric palm sander with #80 grit sandpaper to remove installation and transportation scratches. Sand the deck lightly, while paying attention to visible imperfections. Blow or sweep the dust off and a coat of exterior hardwood oil for decking can be applied.

Note

Wear protective gear to prevent dust inhalation and injuries from woodworking (including while cutting and sanding). It is highly advisable to wear gloves, a dust mask, and protective eyewear.

MAINTENANCE TIPS

Getting the right results is all about preparing the surface of the deck. Following regular annual maintenance also reduces the amount of work required. A light sanding with #80 grit sanding paper with an orbital palm sander is sufficient. Remove the dust that has accumulated and the wood is ready to re-oil.

If maintenance is not performed for a long time and the wood has become grey, pressure wash it and then let it dry for a couple of days. Sand lightly to remove grey spots and oil afterward.

LETTING IPE Black Label ACQUIRE ITS NATURAL COLOR

Gallery

IPE Black label DECKING PROJECT GALLERY

DECKING

TECHNICAL DATA

WHAT MAKES IPE Black Label THE BEST NATURAL DECKING MATERIAL IN THE WORLD

Ipe Black Label wood is naturally fire-resistant is rated A1 for its fire resistance. The wood has high wear durability and resists splinters and checks. It is not uncommon to see Ipe wood decks last 70+ years!

Tropical Forest Products sources Ipe wood from forests that have been legally demarcated for lumber. Our lumber is certified at source and during shipping by an independent third party.

IDENTIFYING CHARACTERISTICS:

Ipe Black Label wood has a natural reddish-brown to dark brown color. The texture is fine to medium.

COMMON APPLICATIONS:

Used as decking, flooring, docks, siding, interior wall panels, and sunrooms.

ORIGIN:

Ipe Black Label is found in the Central and South Americas, but most commonly in Brazil (hence its name).

South America (specifically Brazil) and Central America.

Ipe Black Label– Technical Information

Names: Ipe, Brazilian Walnut, Lapacho

Scientific name: Handroanthus spp.

Weight: 1,100 kg/m3 (69 lbs/ft3)

Specific gravity: 91 (basic), 1.10 (12% MC)

Janka Hardness: 15,620 N (3,510 lbf)

Hardness: An Ipe Black Label deck is approximately three times stronger than teak and eight times harder than California Redwood, tested under ASTM-D143.

Expansion and Contraction: Approximately 5.9% radial, 7.2% tangential, and 12% volumetric. A 6” air-dried board will move an average of 1/16”. There is a small movement after milling as well.

Fire resistance: In Canada, the Ipe Black Label decking board has passed the Intermittent Flame Test and The Spread of Flame Test for the CAN/ULC S107 equivalent of ANSI /UL 790 (Standard Methods of Fire Tests of Roof Coverings) and is rated Class A. This makes it suitable for a rooftop finishing material in non-combustible building class buildings, putting it in the same class as steel. In the U.S., Ipe Black Label wood has been tested by the National Fire Protection Agency, which gave it the highest Flame spread classification: Up to Class A, Uniform Building Code, Class 1.

Termite resistance: Ipe Black Label has received the highest rating from the U.S. Naval Research Laboratory.

Durability and longevity: Untreated Ipe Black Label decking will last 40 years and more. If the deck is oiled or finished on all four sides before installation, it can last 70+ years.

Decking

Accessories

IPE CLIP

The DeckWise® Ipe Clip® EXTREME® Hidden Deck Fastener line features a hardened stainless steel insert with a black oxide coating. The insert is molded inside the fastener for the ultimate concealed look with supreme reinforcing hold-down strength. Every hardwood deck built with the DeckWise® Ipe Clip® EXTREME® hidden deck fastener series will produce a smooth, beautiful and longer-lasting deck for generations to come.

COMPLETE KIT CONTAINS

(175) Ipe Clip® Hidden Deck Fasteners

(190) Stainless Steel Star Drive Deck Screws

(12) 9,5mm (3/8″) Tapered Ipe Plugs

(1) 3,2mm (1/8″) High Speed Drill Bit

(1) T15 Star Drive Tip

(3) Deck Board Spacers*

(1) Instruction Sheet

100 CT. KIT CONTAINS

(100) Ipe Clip® Hidden Deck Fasteners

(100) Stainless Steel Star Drive Deck Screws

(1) Instruction Sheet

COMPLETE KIT CONTAINS

(175) Ipe Clip® Hidden Deck Fasteners

(190) Stainless Steel Star Drive Deck Screws

(12) 9,5mm (3/8″) Tapered Ipe Plugs

(1) 3,2mm (1/8″) High Speed Drill Bit

(1) T15 Star Drive Tip

(3) Deck Board Spacers*

(1) Instruction Sheet

100 CT. KIT CONTAINS

(100) Ipe Clip® Hidden Deck Fasteners

(100) Stainless Steel Star Drive Deck Screws

(1) Instruction Sheet

IPE OIL

The CONTRACTOR BUCKETS from DeckWise® were designed with professional contractors in mind. Containing enough Ipe Clip® fasteners, deck screws and accessories for the largest decking projects; everything deck builders need

to get the job done. DeckWise® Contractor Buckets are available in both 525 and 1050 quantity containers.

2 GAL. CONTRACTOR BUCKET

(525) Ipe Clip® Hidden Deck Fasteners

(570) 4x50mm (#8×2″) Colormatch Black

Stainless Steel Star Drive

Trim-Head Deck Screws

(3) 9,5mm (1/8″) High Speed Drill Bit

(3) T15 Star Drive Tip

(6) Deck Board Spacers*

(1) Instruction Sheet

5 GAL. CONTRACTOR BUCKET

(1050) Ipe Clip® Hidden Deck Fasteners

(1140) 4x50mm (#8×2″) Colormatch Black

Stainless Steel Star Drive Trim-Head

Deck Screws

(5) 9,5mm (1/8″) High Speed Drill Bit

(5) T15 Star Drive Tip

(6) Deck Board Spacers*

(1) Instruction Sheet

2 GAL. CONTRACTOR BUCKET

(525) Ipe Clip® Hidden Deck Fasteners

(570) 4x50mm (#8×2″) Colormatch Black

Stainless Steel Star Drive

Trim-Head Deck Screws

(3) 9,5mm (1/8″) High Speed Drill Bit

(3) T15 Star Drive Tip

(6) Deck Board Spacers*

(1) Instruction Sheet

5 GAL. CONTRACTOR BUCKET

(1050) Ipe Clip® Hidden Deck Fasteners

(1140) 4x50mm (#8×2″) Colormatch Black

Stainless Steel Star Drive Trim-Head

Deck Screws

(5) 9,5mm (1/8″) High Speed Drill Bit

(5) T15 Star Drive Tip

(6) Deck Board Spacers*

(1) Instruction Sheet

IPE PLUGS

IPE PLUGS

When hidden deck fastening is NOT the preferred choice, we have the perfect complete hardwood plug kit for face screwing on the market. Our Master Plug Kit solves the problem by including your choice of four hardwood plug specie (smooth only) including a leading brand of wood glue in every kit. The DeckWise® Master Plug Kit fills in the gap where other so-called “complete wood plug kits” leave open. Finally, builders have the all-in-one system they’ve been asking for.

MASTER PLUG KIT

- 350 ct. or 1,050 ct. Hardwood Plugs

- 350 ct. or 1,050 ct. DeckWise® 4x50mm (#8×2″)

- 305 grade Stainless Steel Screws

- 1 Complete Drill&Drive™ 3-in-1 Drill Bit Set

- 4 oz. Bottle Of Gorilla Glue®

- Substitute screw options available. Call DeckWise® for a quote.

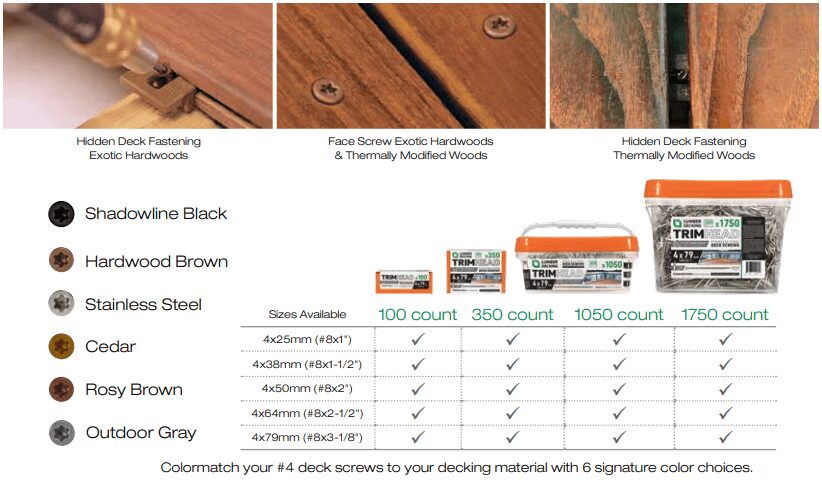

SCREWS

Builders know the DeckWise® brand of stainless steel TRIM-HEAD deck screws are a great way to ensure deck boards stick tight to joists with hidden deck fasteners. As part of the DeckWise® line of deck building products, our Colormatch screws give builders and DIY homeowners a reliable and secure way to fasten most types of decking material. From exotic hardwoods to thermally modified woods and composites, we’ve got you covered.

DECK SCREWS

- 305 grade stainless steel provides anti-corrosion benefits (Also available in 316 marine grade stainless steel. Call for availability.)

- T15 Star Drive finish heads for less stripping

- Type 17 auger tip for easy penetration

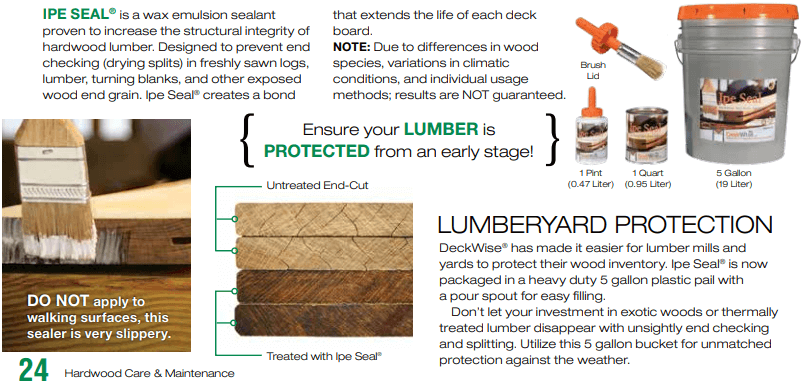

ENDSEAL

DeckWise® WISECOAT® PREMIUM WOOD SEALER is a low VOC non-toxic waterproofer and sealer designed for use on hardwood decking and siding surfaces. This water-based formula utilizes proprietary nanotechnology to create a long-lasting breathable barrier against caustic weather conditions. By coating the wood fibers down at the cellular level, WiseCoat® provides protection from the inside out preventing cracking and splitting of the wood.

The unique formula absorbs deeply, inhibiting water intrusion by penetrating the hardwood surface to protect and stabilize the wood. WiseCoat® helps prevent the damaging effects of mold and mildew, dry rot, peeling, cupping of wood. As a non-film forming water-based sealer, it allows exotic and thermally modified hardwoods to age naturally without decay. WiseCoat® includes a semi-transparent tint that functions as a UV blocker to prevent the hardwood from graying while enhancing the natural grain and texture

APPLICATIONS

- Decks

- Fences

- Siding

- Outdoor

- Furniture

- Docks

- Shake Roofs

- Railings

- Timber Framing

- Play Sets

APPLICATIONS

- Decks

- Fences

- Siding

- Outdoor

- Furniture

- Docks

- Shake Roofs

- Railings

- Timber Framing

- Play Sets

Siding Cladding

Rain Screen

IPE SIDING, CLADDING, AND RAIN SCREENS

Tropical Forest Products has the perfect Ipe wood for sidings, claddings, and rain screens. Our Ipe boards have a rich, lustrous color that elevates the ambiance of the space.

Ipe wood siding, cladding, and rain screens do not require maintenance, with their color and hue turning mildly silver over time. It’s what makes Ipe great for achieving a cottage or urban look, either through a deep reddish-brown color after oiling or its natural hues.

Ipe wood will outlast just about any other wood products – and is far stronger too!

INSPIRING IPE WOOD SIDINGS, CLADDINGS AND RAIN SCREENS

WOOD SIDING WITH STONES

WOOD SIDING IN BATHROOM DECOR

WOOD SIDING IN BATHROOM DECOR

INSTALLATION TIPS FOR IPE SIDING

Allow the Ipe wood siding to acclimatize to its new environment. This will prevent unexpected expansion/shrinking after installation.

A wood sealer or oil should be applied to prevent premature aging, warping, and cupping.

The joist span/furring is advisably kept at a maximum of 16” cc.

Use an end sealer for end cuts to prevent splitting, uneven moisture loss, cupping, and checking.

45° cuts are best avoided in the corners as they can split over time. Advisable that a finishing corner is installed.

Stainless steel screws should be used for maximum longevity.

Exposed sun-facing sides of the Ipe wood should be refreshed every one or two years.

Ensure the construction is performed to specification and complies with building code. For load-bearing structures have the design validated by a structural engineer.

LEGALLY HARVESTED LUMBER

Tropical Forest Products is committed to promoting sustainable forestry, sourcing only legally harvested lumber.

read more- OUR LOCATIONS

- CONTACT US

- SIGN UP

Stay informed about the latest offers, products and sales

- FIND US

- CONTACT US

- SIGN UP